Products for CNC and

motion control applications since 1998.

Design, manufacturing, and support based in the USA.

Click here to see what our customers say about PMDX

We save you money with our $11.00 flat rate Priority Mail shipping for most domestic orders.

General Information

FIND PRODUCTS:

Select Below

To Browse

- Extra I/O & Isolation

- Power Sources

- Test & Development Tools

- Spindle Controllers

- Panels, Pendants & MPGs

- Contactors, Breakers,

SSRs & Power Switches - Noise Filters &

Common Mode Chokes - E-Stop & Control Switches

- Cables & Parallel Ports

- Connectors & Misc

- Software(Mach4,Mach3 etc.)

- Legacy Products

Our Most Popular Products

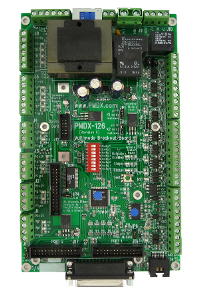

Model PMDX-126 Revision C

Multi-Mode Breakout Board

PMDX-126 board pictured as delivered.

(click on image for higher resolution version)

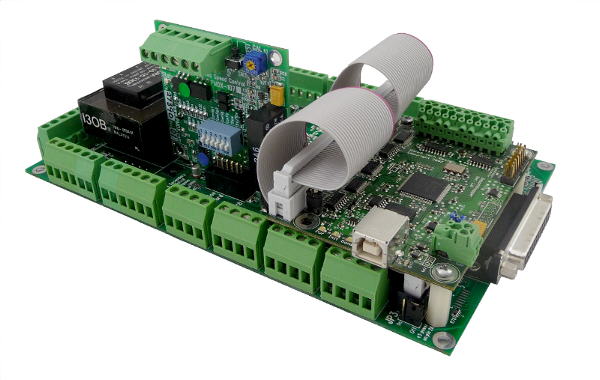

PMDX-126 pictured with PMDX-107, SmoothStepper, and cables.

(click on image for higher resolution version)

The PMDX-126 is a motion control breakout board for interfacing with the parallel port(s) of an IBM-PC style computer or to the USB or Ethernet Smooth-Stepper.

New features of the PMDX-126 Rev C

- Separate and fully isolated Error and Reset terminals for servo drives now work with almost all industrial servo drivers as well as the Geckodrive G320X. Revision C can still be used as direct electrical and mechanical replacement for revision A or revision B versions of the PMDX-126 board.

New features of the PMDX-126 Rev B

- Drop-in replacement, electrically and mechanically, for previous version

- Jumbo Mode supports up to 5 axes from single parallel port

- Added hardware to slave a second motor for driving tandem axis configurations. This together with Jumbo mode makes it possible to drive up to 6 motors with one parallel port.

- One additional input available as pin 10 of 2nd parallel port (can be a general purpose input or act as "Machine Hold"). A total of 10 inputs are now supported.

- Input for pin 15 now offers a jumper option for strong pull-up resistor for use with passive touch probes

- Improved E-Stop circuitry with better noise filtering

- E-Stop output now works even when PMDX-126 does not have power

- Supports the new PMDX-179 Remote Display Board with indicators for E-Stop, Outputs Enabled, Steps Activity, Spindle On, Probe Active, Error Status Codes, Motor Power ON, and Control Power ON

New features of the PMDX-126 (vs. older PMDX-125)

- NEW feature - Inputs can now accept 24 volt PNP sensor signals directly. Many commercial routers and other machines that are upgrade candidates were originally delivered with PNP proximity sensors and this feature makes it much simpler to upgrade them. No external resistors are required. The inputs still directly support NPN sensors, electro-mechanical switches, and logic signals without external resistors or power sources being needed.

- NEW feature - Touch probe signal merge feature allows an active high digitizing probe and an active low tool touch-off probe signal to be combined into a single "probe" signal presented to Mach or other CNC software. No more needing to juggle software configuration based on the task at hand. Designed to work well with the probing features in the new MSM (MachStdMill) screen set.

- NEW feature - K2 relay can be reassigned to pin 14 of port 2 so it can be used even when pin 14 of port 1 is needed as the direction control bit for a PMDX-106 or PMDX-107.

- NEW feature - Option card slot improvements to allow new types of add-on interfaces in the future.

Other features

- Connects to host using a two parallel ports or a single parallel port when using expanded I/O modes. A DB-25 female connector is available for the first parallel port. Additional 26 pin ribbon headers support use of a second parallel port or direct connection to a SmoothStepper. The second port supports 4 input and 4 output signals. The remaining 8 data bits of the second port can be supported as input or output by adding a PMDX-108-Input or PMDX-108-Output board.

- Supports all signals present on the primary standard printer port. (8 data, 5 input, 4 output)

- Supports 4 additional high speed inputs using multiplexed I/O (Enhanced Input Mode with single port and our Mach plug-in), or a second parallel port, or the second port of the SmoothStepper

- Supports 4 additional high speed outputs using a second port or the SmoothStepper

- The additional high speed outputs can be used as step and direction for greater than 4 axis operation when using two ports or the SmoothStepper

- On board LED indicators on all signals

- Terminal strip outputs provided for external LEDs showing status of Power On, E-Stop, Charge Pump, and step signal activity

- All status inputs are optically isolated

- All parallel port signals are terminated and filtered to help resist noise problems

- All step, direction, and control output signals are buffered with 16 mA drivers

- Special isolated interface to sense ERR/RST signal used by Geckodrive servo products

- Special isolated interface can reset and enable Geckodrive servo products from the computer

- The special isolated interface for error sense and reset can also work with many brands of servo drivers other than Gecko.

- E-Stop, Fault, ERR/RST, and "Charge Pump" timeouts turn off all outputs without assistance from host software

- Provides one 30 ampere rated electromechanical relay useful for spindle control

- Provides one 10 ampere rated electromechanical relay for auxiliary functions

- Relays have MOV arc suppressors for longer life of contacts

- Can directly connect with and provide power for PMDX-104 to provide 4 additional 5 ampere relay outputs

- Powered directly by AC mains 115 or 230 volts, switch selectable

- Self resetting poly-fuse protects mains power input

- Can provide +5 power to SmoothStepper through ribbon cables

- Can mount SmoothStepper as a daughter board using standoffs

- Has provision for option card mounting directly (PMDX-107 spindle speed control) or using a ribbon cable to the PMDX-106 and other future products

- Screw terminal blocks with Step, Direction, +5 volts, and Ground for outputs to drivers

- Buffered step and direction available as ribbon header for connection to the PMDX-133/134 simple motherboards for Gecko stepper drivers or to other driver boards with ribbon header inputs for parallel port signals

- Screw terminal blocks for isolated status inputs also provide +5 volts and +12 volts to power sensors such as the PMDX-170, PMDX-171, and NPN proximity sensors

- Status sensor inputs work with mechanical switches, NPN sensors, 5 volt logic signals, and 24 volt powered PNP sensors or PLC outputs

- For mechanical switches and NPN sensors the inputs work by pulling the input to ground and no external resistor is needed

- For logic signals the inputs can be driven by 5 volt CMOS or TTL signals

- For PNP sensors the input is pulled up to 24 volts by the sensor and no external resistor is needed

- Pulse stretch circuit to allow narrow pulse encoder outputs to be used as lathe index signal

- Built in test for generating step signals without need of a host computer

- Built in test step signals run at proper speed for Geckodrive stepper driver smoothness adjustment

- "Charge Pump"/watchdog function has enhanced timing algorithm to avoid teasing by Windows boot process

- Designed for easy interconnection with PMDX-104 and PMDX-108-Output to provide solid state isolated outputs to connect with PLC systems, and power contactors

- Designed for easy interconnection with PMDX-108-Input to provide 8 additional isolated inputs when using a second port parallel port or SmoothStepper

- Microprocessor and programmable logic allow for the future addition of more features

PMDX Breakout board feature comparison table

Note: The step and direction signals used to run this board as a real time CNC device require precise timing. These signals are normally provided by a personal computer motherboard with an onboard parallel port, a parallel port interface card plugged into a motherboard with ISA, PCI, or PCI-Express slots, or by an external device such as the PMDX-410, PMDX-411 or PMDX-422 with Mach4, or the SmoothStepper. You cannot use a USB to printer adapter because it will alter critical timing of CNC control signals. Laptop computers, even those with parallel port interfaces, are not recommended as CNC control computers due to design features that can alter critical timing. If you must use a laptop be prepared to deal with these design issues and/or plan on using an external pulse generating device such as the PMDX-410, PMDX-411 or PMDX-422 with Mach4, or a SmoothStepper.

(for manuals for rev B and rev A boards, see the User's Manual Archive page.

Click here for application notes on using the PMDX-126.

Download the Mach3 Plug-In driver for the

PMDX-126 here.

(NOTE: You only need this plug-in if you are using Expanded Mode.)

(Most people do not need this plug-in.)

The PMDX-126 is priced at $219.00

Cables are sold separately, please order the ones that you need.

Note: Due to the many possible combinations of connecting the PMDX-126, no cables are included.

If you are using a SmoothStepper, you may want to order 2 each PMDX-HDR26Ribbon cables.

If you plan to use a single shared parallel port, you may want to order 1 each PMDX-DB25MtoM cable.

If you plan to use two standard parallel ports, you may want to order 1 each PMDX-DB25Ribbon cable, and 2 each PMDX-DB25MtoM cables.

Use PayPal shopping cart for USA delivery only.

Click here for international orders.

| PMDX-126 >> Multi-Mode Breakout Board Use PayPal shopping cart for USA delivery only, click here for international orders. |

$219.00 |

For International customers or for alternate payment options - click HERE

For accessory cables CLICK HERE

For accessory switches and sensors CLICK HERE

Copyright 2004-2022