Products for CNC and

motion control applications since 1998.

Design, manufacturing, and support based in the USA.

Click here to see what our customers say about PMDX

We save you money with our $13.00 flat rate Priority Mail shipping for most domestic orders.

General Information

FIND PRODUCTS:

Select Below

To Browse

- Listed by Number (All)

- PMDX-340 CNC Control Box

- Motion Controllers

- Breakout Boards

- Extra I/O & Isolation

- Power Sources

- Test & Development Tools

- Spindle Controllers

- Panels, Pendants & MPGs

- Contactors, Breakers,

SSRs & Power Switches - Noise Filters &

Common Mode Chokes - E-Stop & Control Switches

- Cables & Parallel Ports

- Connectors & Misc

- Software(Mach4,Mach3 etc.)

- Legacy Products

Our Most Popular Products

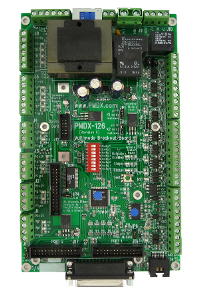

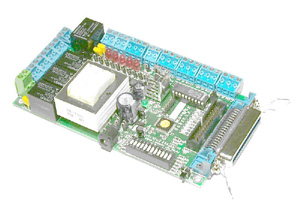

Model PMDX-120

Parallel Port Accessory Module

The PMDX-120 has now transitioned to legacy product status. It is still possible to special order them but they are not recommended for new designs. OEMs and those needing replacements should contact us via email for price and availability quotations.

The PMDX-126 is recommended to users seeking an replacement for the PMDX-120 in new designs.

Click on image for larger view

The PMDX-120 is an accessory sub-system for small CNC machines using stepper motors or step-servos driven from the parallel printer port of a personal computer. It can be used with software such as MACH1, Master5, CNCPRO, EMC, TurboCNC, MaxNC (step/dir version), DANCAD, and probably many others.

It is ideal for use with Gecko, Compumotor, or other motor drivers that accept step and direction inputs. It offers support for all pins of the parallel port and allows for isolation and protection of the parallel port on your computer. Dip switches provide settings for pinout selection, signal inversion, pulse conditioning, and debug/exercise modes.

New version with alternate low voltage power input and 5VDC output.

PMDX-120 Parallel Port Accessory Module Features

Breakout board feature comparison table.

General:

- On board power supply operates from 120 VAC via screw terminal strip or 7 to 9 VAC via a 2.1 mm coaxial power jack. The on board power system provides power to feed opto-isolated inputs of stepper motor drivers and an accessory +5 volt output for encoders or external low power devices. It also provides isolated power for sensing contact closures for status inputs.

- LED "power on" indicator shows presence of input power.

- Pluggable screw terminal strips for connections to motor drivers, relay outputs, and switch inputs.

PC Parallel Port:

- Buffers signals to/from the PC parallel port. Protects PC from damage. Filters noise.

- Allows use of all 8 data bits, 4 control outputs and 5 status inputs.

- Centronics cable connector uses standard PC printer cable.

- Support for optional ribbon cable to remote 25-pin D connector.

Input Status Signals:

- Inputs are opto-isolated and accept contact closure switches or open-collector sensor outputs.

- LED status indicators for each input show when switches are closed.

- DIP switch settable polarity control for each input makes testing limit switch inputs easier.

- Over-voltage protection tolerates direct application of 110VAC to switch inputs without damage to your computer or the PMDX-120 board.

- Special input to accept "Fault" signal from Gecko step-servo drivers or other low current sources.

Relay Contact Outputs:

- Isolated, normally open, "dry circuit", electromechanical relay contact outputs.

- Contacts rated for up to 10 Amps at 125 VAC, 5 Amps at 230 VAC, or 5 Amps at 50 VDC.

- LED status indicators show when relays are on.

- MOV surge arrestors protect relay contacts from arcing.

Motor Step/Direction:

- Independent connectors for 4 axes of step and direction signals.

- Jumper selectable common reference can be either Ground or +5VDC as is often used for motor drivers with opto-isolated inputs for step and direction.

- User replaceable buffer chip on step and direction outputs.

- DIP switch selectable pinout mapping of data bits to step and direction outputs. Supports EMC, Master5, TurboCNC, MaxNC, TAIG, CNCPro, DanCAM and many others without building custom cables.

- DIP switch setting controls the polarity of the step pulse outputs.

- Can optionally regenerate step pulses to uniform width (lengthens “short” pulses from PC).

- Ability to latch the direction signal on rising or falling edge of input step pulse, thus providing extra hold time for direction signal outputs.

- All step and direction signal processing is in hardware logic, no timing distortion from processing delays.

- Motor activity LED shows presence of step pulses.

Diagnostic Features:

- Allows you to operate motors without a PC connected and test hardware before configuring software.

- Three diagnostic modes provide single step, run while button pressed, run repeating square pattern.

Special Notes:

- The PMDX-120 does not support a "charge pump" like that offered by the Mach software.

- Use with the PMDX-106 spindle controller requires utilizing one pair of axis step and direction signals as the Direction and PWM signals for the PMDX-106 because the extra controls signals on a PMDX-120 are relay output only.

Note: The step and direction signals used to run this board as a real time CNC device require precise timing. These signals are normally provided by a personal computer motherboard with an onboard parallel port, a parallel port interface card plugged into a motherboard with ISA, PCI, or PCI-Express slots, or by an external device such as the SmoothStepper. You cannot use a USB to printer adapter because it will alter critical timing of CNC control signals.

Documentation and Other Useful Files

Download Manual in PDF format here (revision 1.6, 732 KB).

Board layout image with silk-screen legends

A good tutorial on parallel port interfacing can be found HERE

Copyright 2004-2022